|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|||||

|

|

|||||||

|

||||||||||||||||

|

|

|

|

|

|

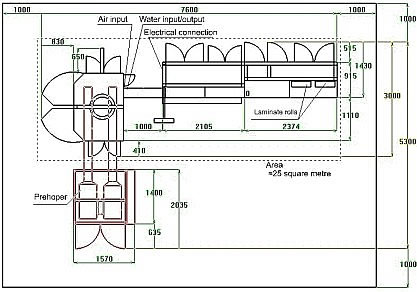

KOMBIS 8000 automatic laminate tube line can be optionally equipped with additional modules to extend its functionality. The machine is build on the modular principle. The tool change has been simplified which reduces considerably the readjustment time and do not require highly qualified personnel. Additionally, a high-frequency top sealing module is offered, as well as a module for production of PBL-tubes, and a module for production of oval tubes. The tightening of the cap-winding is ensured by a specially designed module, which is standard element of the machine as well as the hopper auto filling station |

|

|

|

|

|||||||||||||||||||

|

|

|

|||||||||||||||||