|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|||||

|

|

|||||||

|

|||||||||||||||

|

|

|

|

|

|

The information provided in this section is preliminary!!! Please contact us for up to date parameters. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

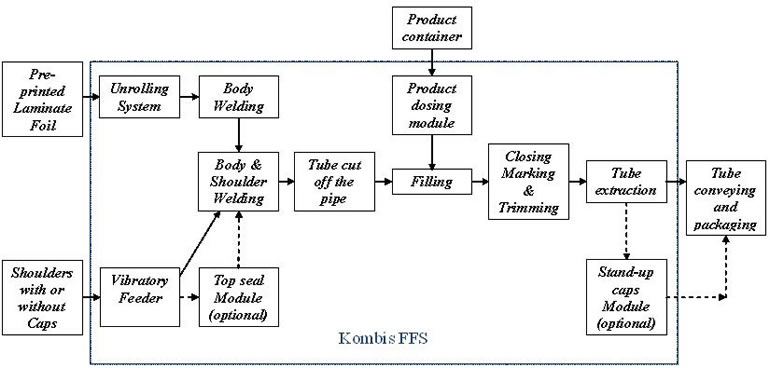

KOMBIS FFS 60 and KOMBIS FFS 200 automatic squeeze laminate tube lines can be optionally equipped with additional optional modules to extend there functionality. For example: module for production of oval tubes, or capping module for attaching stand up caps. The lies is build on modular concept. Tool change is very easy and quick in order to reduce the size change time to minimum. It does not require special skills and highly qualified personnel.

Need to know more? Please check our Q&A or How It Works section for KOMBIS FFSM.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|||||||||||||||

|

|

|

|||||||||||||